The Washington Nanofabrication Facility (WNF) supports the UPWARDS experiential learning pillar in various ways.

The WNF hires undergraduate research assistants (URAs) to support lab operations and perform research under staff supervision. In addition to acquiring basic cleanroom and semiconductor backgrounds, these students learn skills such as the design of experiments (DoE) and data analysis. Many WNF URAs present at the University of Washington Undergraduate Research Symposium.

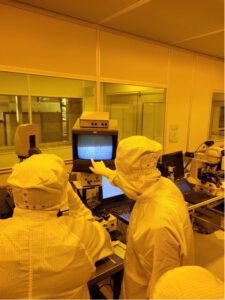

The WNF hosts one-week nanofabrication workshops that act as an introduction to semiconductor fabrication. Students in these courses attend lectures by WNF staff detailing different process modules in semiconductor manufacturing, such as lithography, etch, deposition, and back end of line. They also spend almost 20 hours in the cleanroom building devices such as resistors, capacitors and diodes.

Students and industrial researchers complete rigorous safety training before working in the WNF cleanroom. Once inside the lab, the WNF staff trains users on the tools necessary for their research. This hands-on approach to training prepares the students to be independent workers and exposes them to equipment-performing processes like those used in industrial cleanrooms.

The WNF supports various undergraduate and graduate courses. Students taking the EE527 Microfabrication class spend 6 lab sessions building devices in the cleanroom. WNF staff host tours around the cleanroom for courses such as EE504, Introduction to

Micro-Electro-Mechanical-Systems (MEMS). For EE482, Semiconductor Devices, students plan to visit the lab and build simple structures to understand semiconductor processing better.

WNF is an open-access nanofabrication facility at the University of Washington. It is part of the UW Institute for Nano-engineered Systems (NanoES) and the National Science Foundation’s National Nanotechnology Coordinated Infrastructure (NNCI).